TOSCANER-30000μFD-ZII Series

X-Ray Nondestructive Inspection Systems

TOSCANER-32300μFD-ZII and TOSCANER-33000μFD-ZII high-resolution micro-focus CT scanners

| Applications | Small electronic parts, Chip mounted boards, aluminum die castings, batteries, molded components, resins, fibers, etc. |

|---|

The TOSCANER-30000μ series is the first micro-focus CT scanner in the industry to incorporate a flat panel detector (FPD). The FPD satisfies various needs, including defect analysis and dimensional measurement using scanned data. Select from either a standard 8-inch FPD or a 16-inch FPD with higher image quality.

FEATURES

X-ray generator with an energy output of 230 kV or 300 kV

and a spatial resolution of 5 μm

The reflective micro-focus X-ray generator (with a maximum tube voltage of 230 kV or 300 kV and a high exposure rate) and the FPD X-ray detector make it possible to capture images at resolutions down to as little as 5 μm.

Choose from a 230-kV X-ray generator or a 300-kV model.

High-resolution, high-contrast imaging

The FPD does not produce the geometric image distortion that occurs with other types of X-ray detector. Due to the high contrast achieved across the entire X-ray energy range, the FPD produces fluoroscopic and CT images with a high dynamic range.

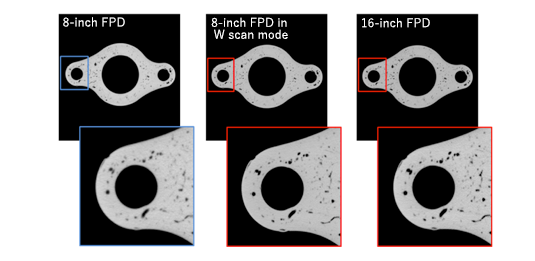

Toshiba’s proprietary W scan mode

The TOSCANER-30000μFD-ZII series provides a unique scan mode that allows you to select either wide-area or high-resolution scanning.

In W scan mode, the 8-inch FPD provides image resolution equivalent to that of a 16-inch FPD.

Outstanding operability

The One-Click Scan feature simplifies the setting of CT scan conditions and automates various correction and calibration settings. You can also specify the CT slice position on a fluoroscopic image, while the cone beam scanner can obtain up to 2048 tomographic images per scan and reconstruct them into a 3D image.

Double safety structure and enhanced maintainability

With a high-voltage generator built into the CT scanner, there is no need for a high voltage cable—thus eliminating the need for time-consuming cable greasing work. The built-in high-voltage generator eliminates cable damage issues resulting from electrical discharges in the X-ray tube. In addition, the built-in high-voltage generator provides an enhanced level of safety since it is not exposed.The click-in cathode assembly on the X-ray generator allows one-touch replacement of filaments. Furthermore, the filament does not require axial adjustment.

IMAGE EXAMPLES

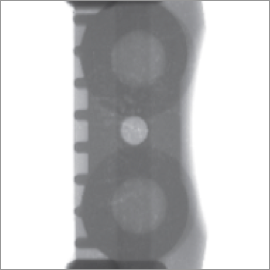

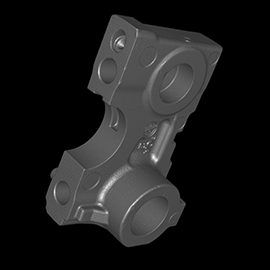

Aluminum die castingCourtesy: Toshiba Machine Co., Ltd.

SPECIFICATION

| Key Specifications | ||

|---|---|---|

| Model | TOSCANER-32300μFD-ZⅡ | TOSCANER-33000μFD-ZⅡ |

| X-ray generator | 230kV | 300kV |

| Minimum X-ray focal spot size | 4μm | |

| X-ray detector | Selectable from 8-inch and 16-inch flat panel detectors (FPDs) | |

| Spatial resolution | 5μm | |

| Maximum sample size and weight | φ420×H450 mm/20kg | |

| Maximum scan area | φ420×H320 mm (8-inch/16-inch) | |

| External dimensions (W×D×H) | W2380×D1670×H1800 mm | W2380×D1670×H1805 mm |

| Main unit weight | Approx. 4000kg | Approx. 4800kg |

| Leakage dose | 1 μSv/h or less | 2 μSv/h or less |

| Power supply / ground | Single-phase 100 VAC, 4 kVA / Earth resistance: 100 Ω or less | |

| X-ray generator | 230kV |

|---|---|

| X-ray generator | 4μm |

| Minimum X-ray focal spot size | Selectable from 8-inch and 16-inch flat panel detectors (FPDs) |

| Spatial resolution | 5μm |

| Maximum sample size and weight | φ420×H450 mm/20kg |

| Maximum scan area | φ420×H320 mm (8-inch/16-inch) |

| External dimensions (W×D×H) | W2380×D1670×H1800 mm |

| Main unit weight | Approx. 4000 kg |

| Leakage dose | 1 μSv/h or less |

| Power supply / ground | Single-phase 100 VAC, 4 kVA / Earth resistance: 100 Ω or less |

| X-ray generator | 300kV |

|---|---|

| Minimum X-ray focal spot size | 4μm |

| X-ray detector | Selectable from 8-inch and 16-inch flat panel detectors (FPDs) |

| Spatial resolution | 5μm |

| Maximum sample size and weight | φ420×H450 mm/20kg |

| Maximum scan area | φ420×H320 mm (8-inch/16-inch) |

| External dimensions (W×D×H) | W2380×D1670×H1805 mm |

| Main unit weight | Approx. 4800 kg |

| Leakage dose | 2 μSv/h or less |

| Power supply / ground | Single-phase 100 VAC, 4 kVA / Earth resistance: 100 Ω or less |

CASE EXAMPLE

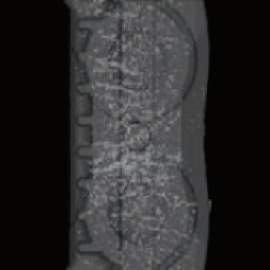

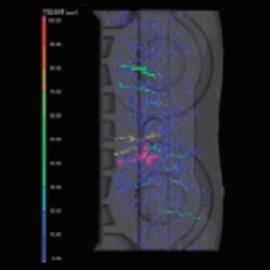

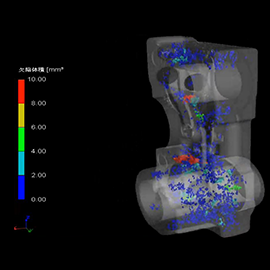

Analysis of an aluminum die-cast workpiece (cavities)

The following video shows cavities with diameters of several hundreds of micrometers, with different volume ranges displayed in different colors.

In addition, the TOSCANER-30000μFD-ZII series can display histograms based on the range of cavity volumes and measure the number of voxels occupied by cavities and their surface areas.

CT image of an aluminum die casting

(3D rendering)

Automatic cavity detection

Application to cultural assets

Because they enable us to observe the internal structure of a scanned object—which would otherwise be invisible to the naked eye—X-ray inspection systems are utilized for the evaluation and restoration of cultural heritage items. X-ray CT scanners are employed to produce 3D representations of not only internal structures but also surface details, which helps researchers make new discoveries.

3D CT image of a cultural asset